- GMZ Enerji Sistemleri Sanayi ve Ticaret Limited Şirketi

- 75. Yıl OSB Neighborhood, Bilim Street No: 5 – Interior Door No: 503, Odunpazarı/Eskişehir, Türkiye

- bilgi@gmzenerji.com

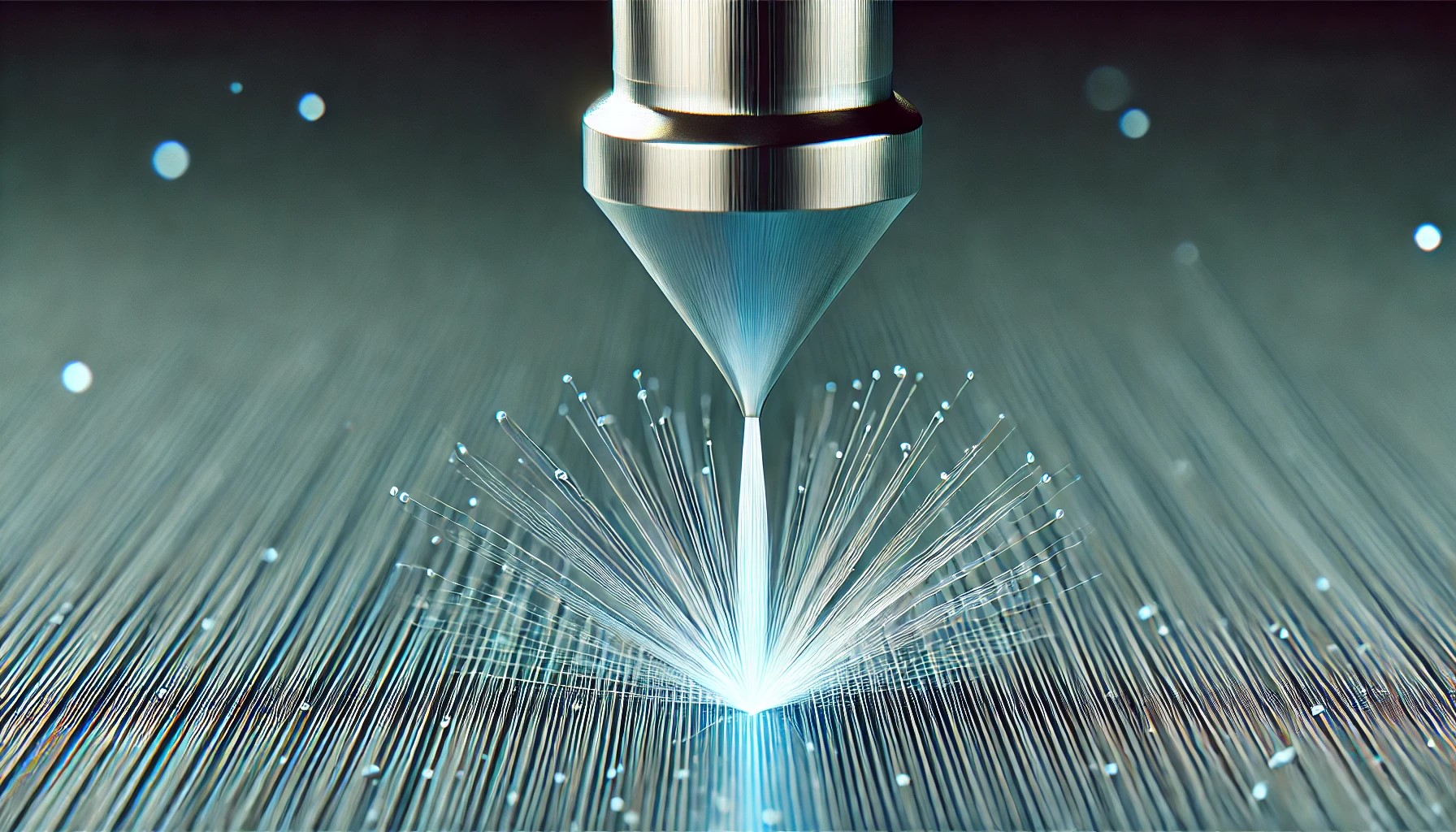

Electrospinning Equipment

Electrospinning Equipment

Fiber materials are widely used in various industries such as wastewater treatment, energy storage, tissue engineering, drug delivery, heavy metal detection, and thermal insulation. These materials are valued for their large surface area, high porosity, excellent mechanical performance, and low density.

Electrospinning is a simple yet versatile method for producing these fibers. Despite its simplicity, several factors affect fiber formation, and the high voltage applied during the process can cause bending instabilities, resulting in non-uniform fibers.

Why Choose GMZ Enerji’s Electrospinning Solutions?

At GMZ Enerji, we tackle common challenges in electrospinning with innovative solutions designed to improve the repeatability and quality of fiber production:

Correcting Irregularities with Magnetic Fields:

- Reduced material waste

- Lower energy consumption

- Fibers with more uniform diameters

- More homogeneous thickness

Real-Time Thickness Measurement:

To address the limitations of real-time thickness measurement in current systems, we are developing methods that include:

- Real-time thickness measurement using sensors based on light transmittance

- Image processing techniques to assess fiber mat thickness

By integrating these advancements, GMZ Enerji ensures that the electrospinning process becomes more efficient, reliable, and capable of producing high-performance fibers with consistent quality.